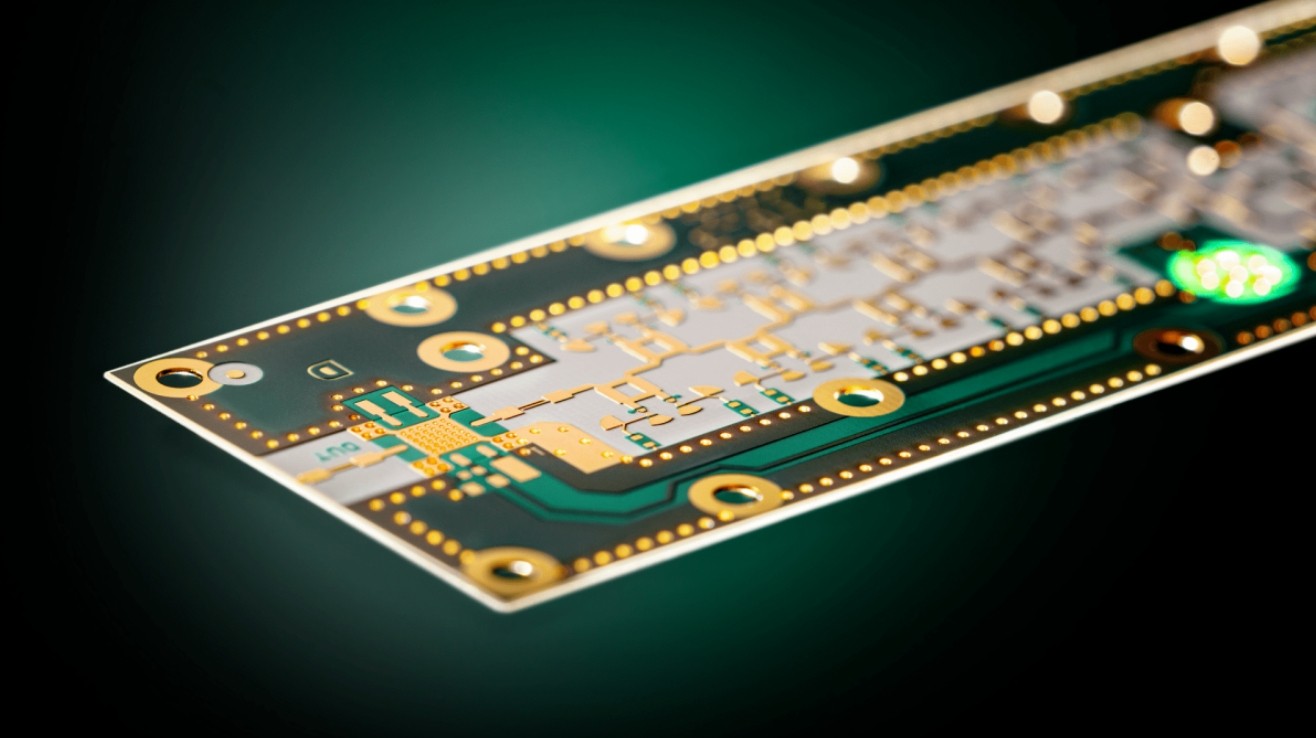

Application Scenarios and Future Trends of High-Frequency Printed Circuit Boards

In today's connected world, where communication and data transmission are critical, high-frequency PCBs have become indispensable. These PCBs are designed to handle signals in the gigahertz range, ensuring reliable transmission and reception of high-frequency signals, making them critical in numerous industries.

High Frequency Printed Circuit Boards in Telecommunications

Widespread applications in the telecom industry rely heavily on high-frequency PCBs. From mobile phones to satellite communication systems, these PCBs enable the seamless transmission of data and voice signals over long distances. The use of high-frequency PCBs ensures minimal signal loss, improves signal integrity, and enhances the overall performance of telecom equipment.

One notable application is base station equipment used in cellular networks. These base stations require high-frequency PCBs to handle the large amounts of data and high-frequency signals involved in wireless communications. In addition, high-frequency PCBs are used in radar systems, microwave communication equipment, and satellite receivers for efficient signal processing and transmission.

High Frequency Printed Circuit Boards for Aerospace and Defense

The aerospace and defense sector is another area that has greatly benefited from the use of high-frequency PCBs. In these industries, high-frequency PCBs are used in a range of applications including radar systems, satellite communication systems, avionics, and missile guidance systems. These applications require PCBs that can accurately handle high-frequency signals.

The rigorous requirements of aerospace and defense applications require high-performance PCBs that can withstand harsh environments, vibration, and extreme temperatures. High-frequency PCBs play a key role in ensuring reliable and efficient communication, navigation, and data processing in these complex systems. Prestigious projects such as space exploration missions and advanced military equipment rely heavily on high-frequency PCBs to deliver superior performance and reliability.

High Frequency Printed Circuit Boards in Medical Equipment

The medical industry has also embraced the use of high-frequency PCBs in various cutting-edge devices. Medical devices such as MRI machines, ultrasound equipment, and wireless monitoring systems often require high-frequency signal processing for accurate diagnosis and treatment. The high-frequency PCB can realize the efficient transmission of signals and ensure the quality and reliability of medical data.

Additionally, the miniaturization of medical devices drives the need for high-density interconnects and advanced signal processing capabilities. High-frequency PCBs can integrate complex circuits into smaller form factors, making medical devices more portable and convenient. From wearable health monitors to life-saving imaging devices, high-frequency PCBs contribute to the advancement of healthcare technology.

High-Frequency Printed Circuit Boards in the Automotive Industry

With the application of high-frequency PCBs in modern vehicles, the automotive industry has undergone major changes. With the rise of electric vehicles (EV), advanced driver assistance systems (ADAS), and in-vehicle connectivity, high-frequency PCBs are critical to enabling high-speed data communication and signal processing.

In electric vehicles, high-frequency PCBs are used in power electronics, battery management systems, and motor control units. These PCBs ensure efficient power distribution, accurate monitoring of battery performance, and precise control of electric motors. Additionally, in-vehicle infotainment systems, GPS navigation, and advanced driver assistance function rely heavily on high-frequency PCBs for seamless connectivity and real-time data processing.

High Frequency Printed Circuit Boards in Consumer Electronics

Consumer electronics have advanced significantly in recent years, and high-frequency PCBs have played a key role in enabling these innovations. Devices such as smartphones, tablets, smartwatches, and wireless communication devices rely on high-frequency PCBs for efficient signal transmission and processing.

High-frequency PCBs enable faster data transfer rates, improved wireless connectivity, and enhanced device performance. They help integrate functions such as wireless charging, NFC (Near Field Communication), and high-speed data interfaces in compact and stylish consumer electronics devices. High-frequency PCBs have become essential components in the consumer electronics industry, enabling seamless communication and enhancing the user experience.

Challenges and Considerations of Designing High-Frequency PCBs

The design and manufacture of high-frequency PCBs present a number of challenges that need to be addressed for optimal performance. Factors such as impedance control, signal integrity, and electromagnetic interference (EMI) mitigation are key considerations during the design process.

Achieving precise impedance control is critical for high-frequency PCBs. Impedance mismatches can cause signal reflections and loss, resulting in degraded performance. Designers must carefully select materials with consistent dielectric properties and accurately calculate trace width, substrate thickness, and copper thickness to maintain the desired impedance.

Signal integrity is another important aspect to consider. High-frequency signals are more susceptible to noise and distortion, which can affect system accuracy and reliability. Techniques such as controlled impedance routing, proper ground and power plane design, and shielding help preserve signal integrity and minimize the effects of electromagnetic interference.

The manufacturing process also plays an important role in the performance of high-frequency PCBs. Precise fabrication techniques such as controlled impedance fabrication, high-precision etching, and controlled copper plating are necessary to ensure the desired impedance characteristics and minimize signal loss.

Future Trends and Innovations

The future of high-frequency PCBs holds exciting possibilities. As technology continues to advance, new applications for high-frequency PCBs are emerging in various industries. Some trends and innovations to watch out for include:

5G and Beyond: The deployment of 5G networks is driving the need for higher-frequency PCBs with higher data transfer rates and lower latency. As the world moves towards next-generation wireless communications, high-frequency PCBs will play a key role in enabling faster, more reliable connections.

Internet of Things (IoT): The proliferation of IoT devices requires high-frequency PCBs capable of handling the ever-increasing amounts of data generated by interconnected devices. High-frequency PCBs will enable seamless communication between IoT devices, enabling a smarter, more connected world.

Flexible and Wearable Electronics: Flexible high-frequency PCBs are becoming increasingly important in wearable devices and flexible electronics. These PCBs can conform to complex shapes and transmit high-frequency signals in flexible substrates, opening up new possibilities for wearable technology and flexible electronics applications.

Advances in Materials: Ongoing research and development of materials such as low-loss laminates, high-frequency substrates, and conductive inks will continue to improve the performance and functionality of high-frequency PCBs. These advances will help improve signal integrity, reduce loss, and increase reliability.

Integration of RF and Digital Circuits: The integration of radio frequency (RF) and digital circuits on a single PCB is a growing trend. This integration allows compact design and efficient communication between different circuits, making high-frequency PCBs essential for seamless RF-digital integration.

As technology evolves, high-frequency PCBs will continue to play an important role in powering advanced applications, enhancing connectivity, and driving innovation across industries.

The above introduces the application of high-frequency PCB boards. If you want to buy high-frequency PCB boards or other PCB boards, please contact us.

Singo is a professional custom circuit board manufacturer. Our company specializes in electronic PCB assembly. Since 2006, mainly engaged in PCB assembly and OEM/ODM electronic manufacturing services. The products involve home appliances, digital products, industrial control, medical equipment, etc. After years of hard work, we have established long-term cooperative relationships with some internationally renowned companies. Our top priority is to deliver high standards of work and fast turnaround times in everything we do for you. With advanced equipment and skilled engineers, we can provide a variety of electronic manufacturing services and can complete short-term production of up to 10,000 pieces at a time.