Why use Conformal Coating?

To protect a printed circuit board (PCB) from the elements, including moisture, dust and extreme temperatures, conformal coatings are often applied. They form a thin polymeric film and can be applied either by spray coating, brushing, dip coating, etc, and usually take up little space. They significantly improve the performance and prolong the life span of PCBs. Prevent the premature breakdown of the components.

Which industry requires Conformal Coatings?

The use of conformal coatings is particularly important in automotive, military, aerospace, marine, lighting, industrial and green energy applications. However due to the rapid expansion of the electronics industry, conformal coatings are also finding their way into the domestic and mobile electronics industries, providing the necessary combination of high performance and reliability within a vast array of electronic devices.

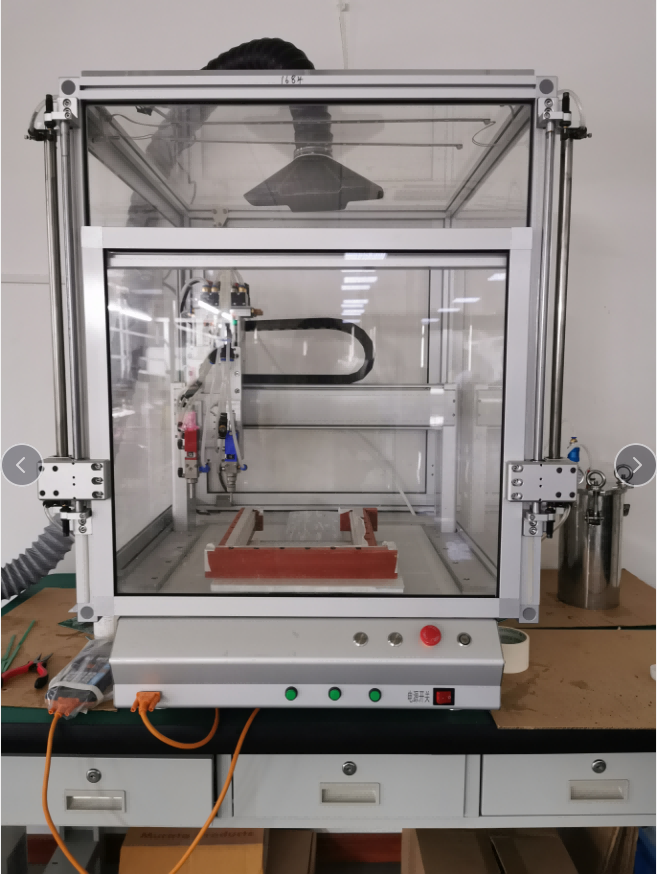

Robotic Spray vs Traditional applications:

The method of application will depend on the customer requirements of the turnkey pcb assembly, but we prefers spray method for consistency in overall coating thickness. There are often select components on a pcb board assembly that will not be required to be coated. The traditional way is to block out or mask the selected components with tape. This is time consuming, costly and a possibility that the component can be damaged on the SMT assembly when removing. The robotic method can be programmed accurately to spray around the parts thus ensuring no component damage from masking and maintain a repeatable coating thickness.