Future Trends of Circuit Boards

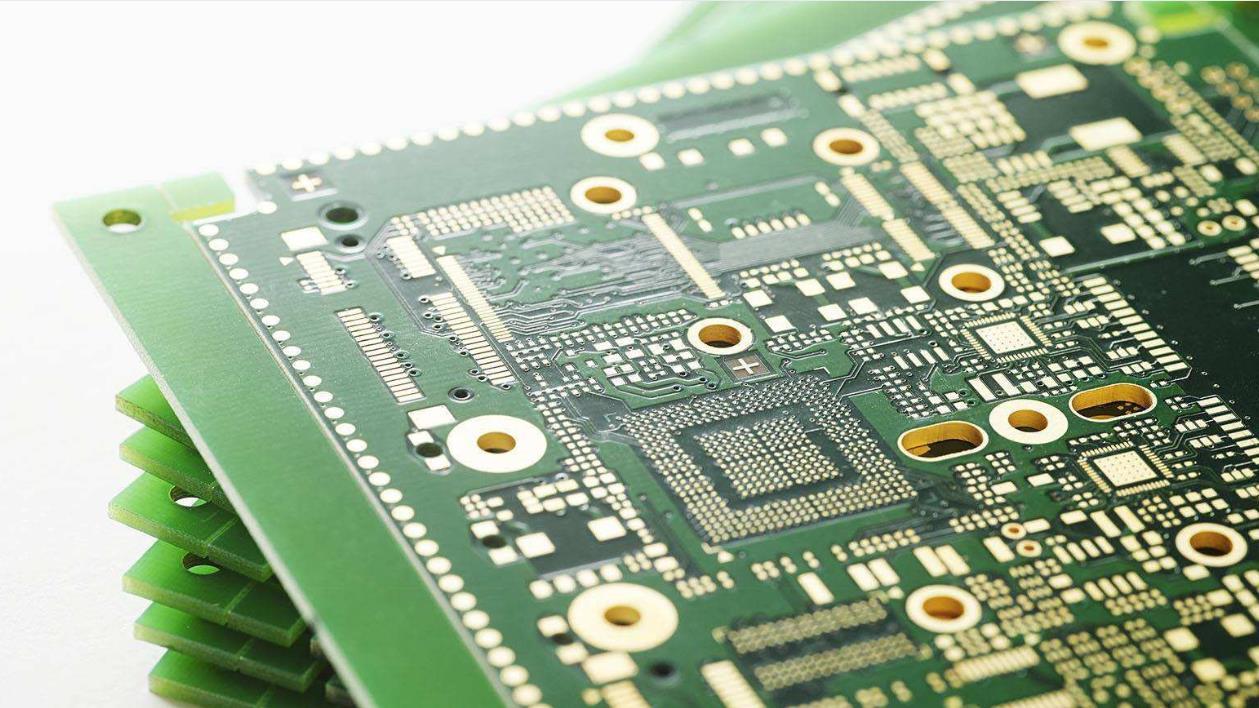

As consumer demand for faster, smaller, and more efficient devices continues to increase, so does the demand for printed circuit boards. PCBs are the backbone of all electronic devices. They affect their size, speed, and function.

In this sense, the continued need for technological advancement and implementation will inevitably require advancements in PCBs. In this post, we'll cover three of the most likely future trends for circuit boards.

What is the Future of Circuit Boards?

3D Printed Electronics

3D printing technology is one of the most interesting and innovative technological advancements in recent years. From 3D printing tools to complex digital designs, 3D printing technology is used in almost every industry, and PCB manufacturing is no exception.

Already used in PCB manufacturing, the technology is expected to revolutionize the way future electrical systems are designed. The technology allows PCB manufacturers to print substrate projects layer by layer, then add liquid ink to parts that contain electrical functions. Future advancements in this mode of PCB manufacturing will pave the way for circuit innovations that can take any conceivable shape.

Flexible Printed Circuit Board

Between flexible displays, wearable electronics, and medical applications, the electronics industry is increasingly turning to flexible PCBs. Compared to rigid PCBs, flexible PCBs can withstand more stress. They can even fold into awkward 3D spaces. This makes them very useful in applications where bending occurs frequently.

Biodegradable PCBs

E-waste is one of the biggest environmental problems of modern times. Given the amount of electronics a person uses in a decade, coupled with the industry's trend toward short-lived electronics, we need a radical solution to minimize e-waste.

Some scientists have suggested that we solve the contamination problem by changing the PCB itself. This will mean switching from traditional PCB manufacturing materials to more environmentally friendly and biodegradable materials. There's also talk of swapping out the harmful etching chemicals used in today's assembly process for greener alternatives.

Bottom Line

The PCB has come a long way since its invention. What was once a large rigid block is now the slim, compact design we know today. As the future unfolds, we will see further developments in PCB technology. If you want to customize the PCB board, welcome to contact us.

Singo is a professional custom PCB board manufacturer, mainly engaged in PCB assembly and OEM/ODM electronic manufacturing services since 2006. Products involve medical equipment, home appliances, digital products, industrial control, etc. After years of hard work, we have established long-term cooperative relations with some well-known international companies. If you are looking for an electronic PCBA OEM/ODM supplier, welcome to contact us, we sincerely welcome you to visit our company.