The Importance of Printed Circuit Boards for Electronic Products

Printed circuit boards are the backbone of most electronic devices. They are everywhere from cell phones to computers, but what exactly is a PCB? Let's explore the many capabilities of this complex technology and why they are so important.

What is PCB?

A printed circuit board, or PCB for short, is an electronic board in which metal circuits are embedded to connect different components on a device. It consists of layers that are individually etched and then laminated together to form a pattern called a trace.

These patterns are where signals pass through the board and pass information between different parts of the circuit.

Circuit boards come in many shapes and sizes, depending on what they're used for - some have holes drilled in them, while others may only need small pads to connect components.

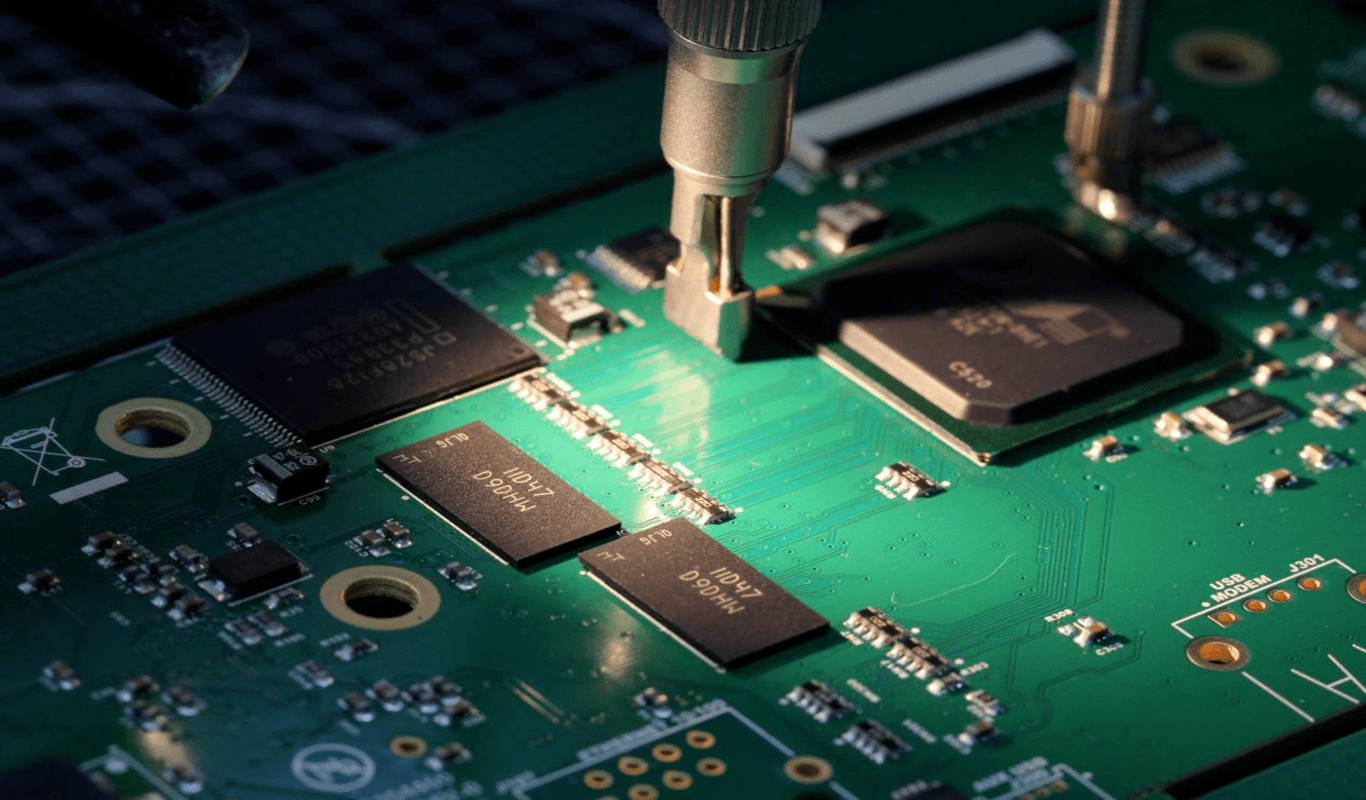

Electronic devices built on a PCB are connected to the board via pads, which come in two different forms - through-hole and surface mount. Through-holes are components that have wires or pins drilled through the board, while on-board devices (usually SMDs) are connected to the top of the pads by molten solder.

There are pros and cons to both ways of connecting components, but for the most part, through-holes have become less common due to their size and weight, while SMDs are becoming more popular because they are smaller and faster.

Types of PCB boards

If you're looking for a PCB for your next project, there are plenty of options to choose from. There are flexible PCBs, rigid PCBs, single-layer boards, and multi-layer boards. And different materials such as FR4 as glass epoxy laminate or CEM.

Flexible printed circuit board

They are made of silicone or polyimide and can be bent over sharp corners without breaking.

They come in two different types: rigid-flex, which is a combination of rigid and flexible PCBs, and foldable, which can be folded in half without breaking.

Single and multilayer boards

The thickness of the boards also varies, with some boards having only one layer, while others have as many as 16 layers. The more layers a board has on top of each other, the more complex the board becomes.

But as complexity increases, so does functionality. Single-layer boards are used for simple devices, while multi-layer boards are used for more complex devices.

What is the use of PCB?

Almost every electronic device you can think of contains at least one PCB. Phones, computers, tablets, TVs, cars-you name it.

The main function of a PCB is to connect different components on a device and allow communication between them.

For example, your phone has a PCB that connects the screen, buttons, and circuits on the back. Without this board, these components would not be able to communicate with each other and the phone would stop functioning.

PCBs also play an important role in protecting these components from damage. By placing them on a board and shielding them with a metal layer, you can create a Faraday cage to protect them from external disturbances like electromagnetic radiation.

The benefits of PCB

There are many benefits to using printed circuit boards. The first is that they allow products to be smaller and more portable.

The circuit on the PCB takes up much less space than the individual components themselves, so you end up with a smaller product. It also makes it easier to put different parts of the circuit together and route them where they are needed.

Second, they are very durable and durable. They can withstand a lot of damage, such as heat, moisture, and even physical force, without breaking. This makes them ideal for use in areas that are hazardous to electronics-such as under the hood of a car where it's exposed to substances like oil and water.

Subjecting a circuit board to these elements is critical to ensuring that it continues to function properly, especially in the case of critical components like braking systems.

Third, they are very safe. The circuits on the PCB are encapsulated, so it is nearly impossible to touch both contacts with bare skin at the same time. This eliminates the chance of you getting an electric shock from the device.

Fourth, PCBs are very efficient and economical. They allow equipment to be manufactured with fewer components, saving you and your business costs.

Finally, PCBs are easy to repair and recycle. If a component on the board fails, it's usually easier to fix than it's located elsewhere in the circuit. When the circuit board finally reaches its end of life, it can be recycled without any negative impact on the environment.

Without a printed circuit board, our equipment would not function. They are essential for connecting different components and allowing communication between them. Additionally, the PCB helps protect these components from damage and interference.

When next time you're on your phone or computer, take a moment to admire the hidden printed circuit board that makes it all possible! If you want to know more or want to customize a PCB board, welcome to contact us.

Singo Tech Co. Ltd. is a professional custom circuit board manufacturer. Our company has been specialized in electronic PCB assembly. Mainly engaged in PCB assembly and OEM/ODM electronic manufacturing services since 2006. The products involve home appliances, digital products, industrial control, and medical equipment. After years of hard work, we have established long-term cooperative relations with some internationally renowned companies.